Lithium battery combination cap

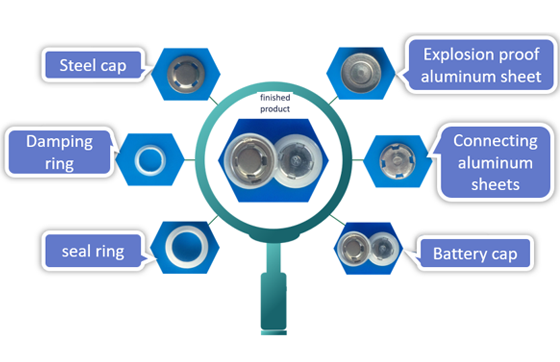

The lithium battery combination cap is an important component of cylindrical lithium batteries, whose core function is to ensure the safety and performance stability of the battery. It is mainly used to seal the battery assembly, prevent internal components from being contaminated by external substances, and also protect and fix the battery pack. It is usually composed of components such as caps, conductive plates, limit plates, elastic blocks, etc. Through the clever combination of these components, rapid assembly and enhanced sealing of lithium batteries are achieved. Specifically, it includes the following key functions:

- Quick assembly;

- Enhance sealing performance;

- Thermal runaway protection;

- Explosion proof function.

Prevent short circuits and explosions caused by residual battery power

Used lithium batteries may have residual power at both ends, and installing protective caps can prevent explosions caused by short circuits.

Overcharge protection

When the charging reaches a certain level, it will be forced to terminate to prevent battery overheating and damage.

External short circuit protection

Some caps are equipped with PTC protection components inside, which increase the resistance significantly when reaching a certain temperature, preventing the battery from discharging and protecting the battery from external short circuits.

Ensure safety performance

The combination cap is designed with an explosion-proof system. When the internal pressure of the battery increases, the pressure is quickly released through the pressure relief hole to ensure the safety performance of the battery.

Maximum security protection

When the internal short circuit of the battery generates heat, the explosion-proof aluminum sheet inside the explosion-proof combination cap precisely operates according to the pressure it is subjected to. Through the dual insurance of CID disconnection and VENT explosion, it greatly reduces the occurrence of fire and eliminates the possibility of explosion.

Maximum Product Quality Assurance

Defect rate PPM: Poor appearance PPM<10, poor size and performance PPM<0.3.

Passed ISO9001:2015, RoHS testing, and halogen testing.

Ensure product quality and adaptability through the following aspects of electrical protection

Material reliability

The raw materials used for metal and plastic parts are sourced from well-known state-owned enterprises such as Sinopec and Baosteel in Shanghai.

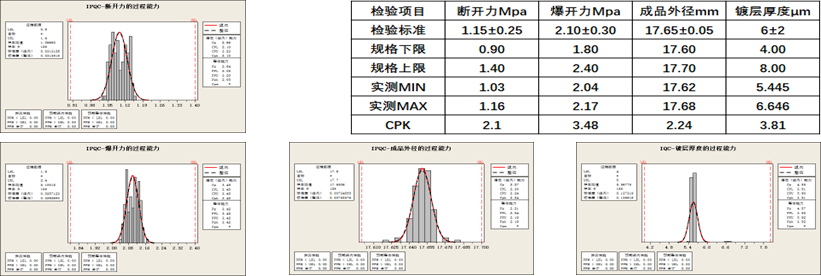

Component consistency

The components are formed by precision injection molds and stamping molds, with main dimensions of CPK>1.67

Customer Applicability

The color of the sealing ring, adhesive sealing process, and specifications and models of the combination cap can be customized according to the needs of different customers 。

Taking the 1802 combination cap as an example, the bursting force, breaking force, size, and coating thickness CPK are greater than 1.67